Reviewing Your Color Management Strategy: What Variables Are at Play?

January 3, 2023 by Shelby Sapusek

Color management issues often aren’t discovered until we are viewing what we hoped would be the final print product. And since that’s where the problems are found, our instinct tells us that we should fix them there – at the end of the printing process.

However, there are many variables that can affect color quality and consistency; and not all of them are found at the end of the printing process.

Color management is about problem solving and crossing off culprit variables in your process. If you are having trouble with color predictability, quality, and/or consistency, it might be time to review the variables in your color management strategy.

Check Your Software and RIP Settings

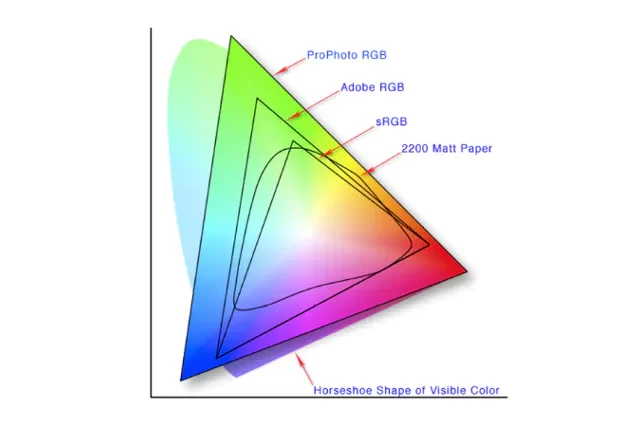

As human beings, we can see millions of colors; approximately 16.8 million actually. But our RGB monitors can only display a fraction of those while our CMYK output devices only have the ability to produce thousands of different colors. It’s no wonder we have so many color expectations that lead to color frustrations.

To help mitigate these frustrations, we can make adjustments to our color management settings at the beginning of the design process.

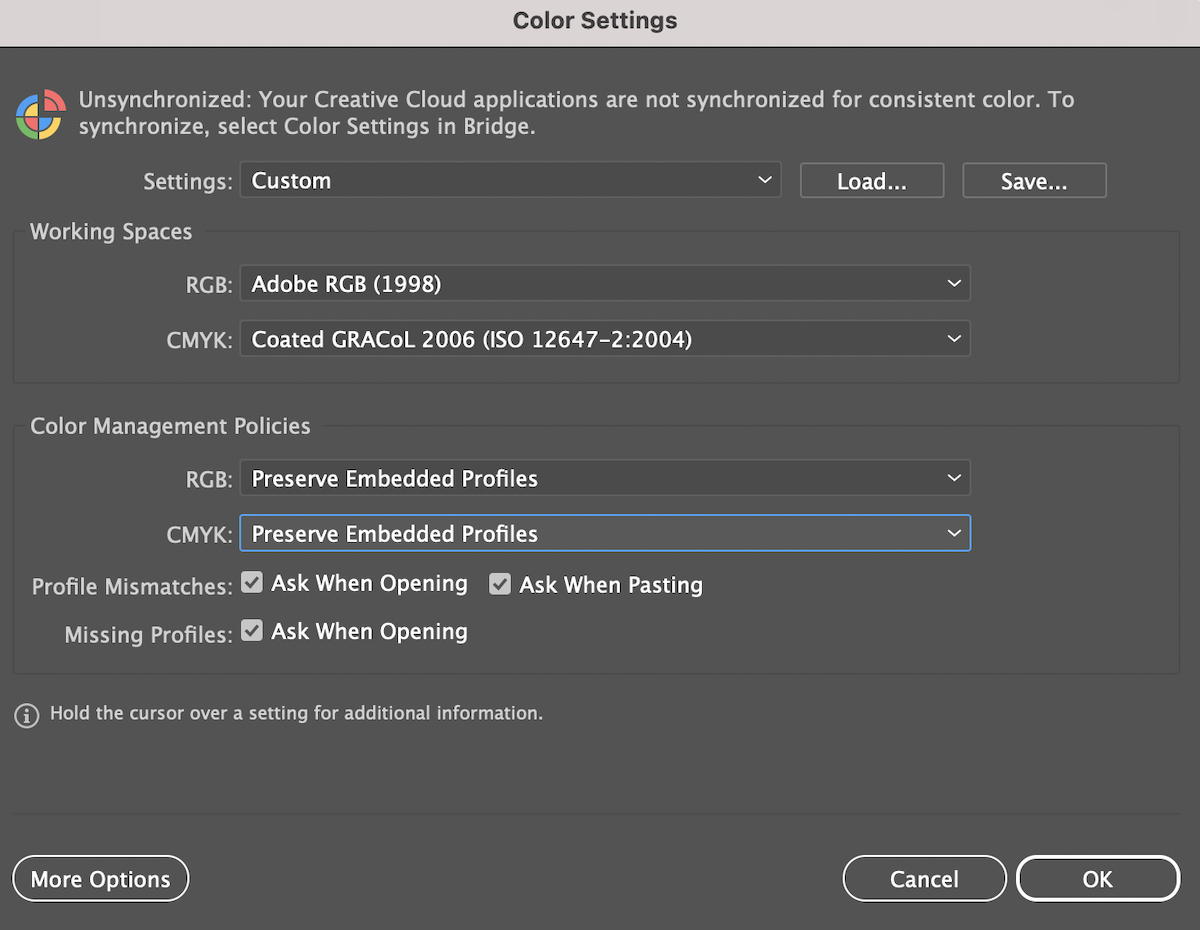

Color management professionals suggest setting the RGB working space to Adobe RGB 1998 and the CMYK working space to Coated GRACol 2006 (ISO 12647-2:2004). These settings can be found in the Adobe software and other design software such as Corel Draw. They also recommend the same settings in the corresponding RIP software.

These settings allow for larger color gamuts in both the design software and our RIP. Check your software settings to ensure you’re using the largest RGB and CMYK color spaces you can.

If you’d like to read more about color management settings and their benefits specifically in the Adobe software, click here for a related article.

Enhance Your Station with Calibration

Another variable that can be checked off at the beginning of your color management strategy list is monitor calibration. It’s a step that is often missed by designers and RIP operators alike.

When your new laptop or monitor arrives, you might be impressed with how the projection looks straight out of the box. It’s very bright and white. Unfortunately, it’s not a good representation or interpretation of how we view color with our eyes. That bright white screen can be detrimental to critical color viewing.

Therefore, it’s necessary to calibrate your monitor to better mimic how our eyes see color. You can learn more about why that’s important and request a free how-to guide by clicking here.

Take the Printing Process into Account

In today’s industry, there are other ways to print rather than just solely ink on paper. Depending on your printing process, you may have other variables that can affect your color management strategy.

For instance, if you’re doing UV (ultraviolet) printing, you’ll need to take your printer’s heat settings and leave time into account. Do you have some dye sublimation in your facility? If so, the heat, time and pressure settings for your heat press matter for color quality.

Understanding the different variables associated with different print methods is invaluable.

Ink, Substrate, Hardware, and Software – Oh My!

Of course, you need to remember the standby common variables in the form of ink, substrate, hardware and software.

Some don’t understand that once a printer is profiled that it must be maintained and assessed at regular intervals. You can’t just make one profile and the printer is calibrated for life.

If you see that your color quality has drifted, it might because one of the standard variables have changed. Have you had to replace a printhead or changed substrates or ink? Has an update to your RIP or design software forced changes to your preferred settings?

Is Re-Calibration Necessary?

To see the condition of your printer, print out a color target and measure it into a color verification software system. This way, you can compare your printer’s quality to a target such as GRACol to determine whether you’ll need to re-calibrate or re-profile your printer.

A number of variables can affect the color quality of your printer. But that might not mean you necessarily have to re-calibrate every time you see changes. Still, it’s important to know and understand the variables in your printing process so you’re able to troubleshoot when color problems arise.

Want to see more articles like this?

Register for a free ColorBase account today and we'll send you fresh Blog content straight to your inbox!

Read more articles

The Most Important Checkbox in your RIP Color Management Settings

If you’re serious about color accuracy in your printshop, you’ve likely explored output profiles for your large format printers….

The Future of Large-Format Printing: AI, Sustainability, and Remote Innovation

This article was previously published on printvergence.com At HP we are already looking to the year ahead and all…

What are the complications of ICC RGB profiles?

As content creators, whether you’re a photographer, graphic designer, or digital artist, understanding the role of ICC RGB colour...